Reduce Costs With Effective Inventory Management

Effective inventory management is crucial for businesses of all sizes. It is the process of overseeing the flow of goods and products in and out of a company. The goal of inventory management is to ensure that the right products are available in the right quantities at the right time, while minimizing costs and maximizing profits.

One of the most significant benefits of effective inventory management is cost reduction. When a company has too much inventory, it ties up capital and increases storage costs. On the other hand, if a company has too little inventory, it risks stockouts, which can lead to lost sales and dissatisfied customers.

Read also:How Much Are Capitals Tickets To See Ovechkin Try To Set Nhl Scoring Record

Effective inventory management can also help businesses identify areas for improvement in their supply chain. By analyzing inventory levels, companies can identify trends and patterns in demand, which can help them make better purchasing decisions.

- How Inventory Management Reduces Costs

- Inventory Management Techniques

- Implementing Inventory Management Software

- Conclusion

How Inventory Management Reduces Costs

Firstly, inventory management helps businesses reduce the carrying costs of inventory. Carrying costs include storage, handling, insurance, and depreciation costs. By keeping inventory levels low, businesses can reduce these expenses, which can have a significant impact on their bottom line.

Secondly, inventory management can help businesses avoid stockouts. Stockouts occur when a business runs out of stock, which can lead to lost sales and dissatisfied customers. By using inventory management techniques such as just-in-time (JIT) inventory, businesses can avoid stockouts and reduce the associated costs.

Thirdly, inventory management can help businesses reduce the cost of obsolete inventory. Obsolete inventory is inventory that is no longer in demand or has expired. By regularly reviewing inventory levels and identifying obsolete inventory, businesses can reduce the associated costs, such as storage and handling costs.

Lastly, inventory management can help businesses reduce the cost of order processing. By consolidating orders, businesses can reduce the number of orders and associated processing costs. This can also lead to better supplier relationships and potentially lower costs for the business.

Inventory Management Techniques

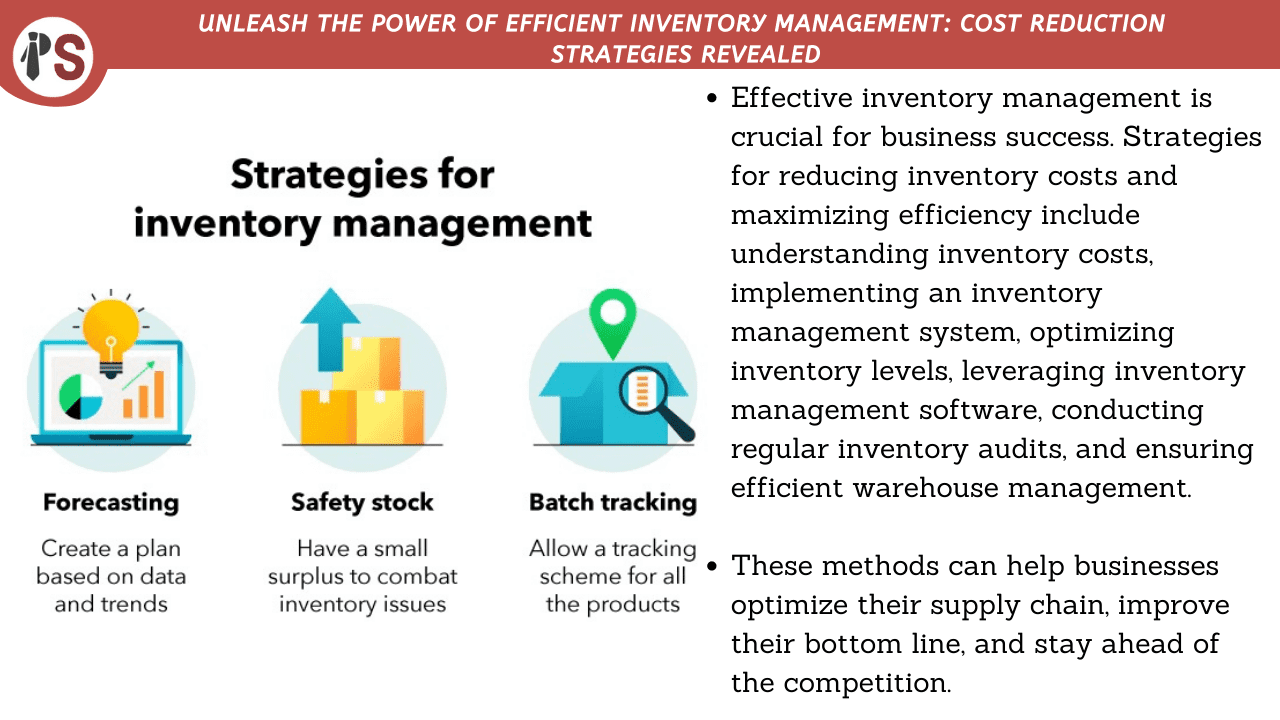

Effective inventory management is crucial for businesses to reduce costs and increase profitability. Here are some inventory management techniques that can help achieve these goals:

Read also:100yearold Nyc Cabaret Singer Shares Her Secret To Longevity Everything About Her Is An Inspiration

ABC Analysis

ABC analysis is a method of categorizing inventory based on its value. The inventory is divided into three categories: A, B, and C. Category A includes high-value items that represent a small percentage of the total inventory but have a significant impact on the business’s revenue. Category B includes moderate-value items that represent a moderate percentage of the inventory. Category C includes low-value items that represent a large percentage of the inventory but have a minimal impact on the business’s revenue. By prioritizing inventory management efforts on category A items, businesses can reduce costs and increase profitability.

Just-In-Time (JIT) Inventory Management

JIT inventory management is a technique that involves ordering inventory only when it is needed, rather than keeping large quantities of inventory on hand. This technique helps businesses reduce inventory carrying costs, such as storage and insurance costs, and minimize the risk of inventory obsolescence. JIT inventory management requires accurate demand forecasting and reliable suppliers to ensure that inventory is delivered on time.

Economic Order Quantity (EOQ)

EOQ is a formula used to determine the optimal order quantity that minimizes total inventory costs. This formula takes into account the cost of ordering inventory, the cost of holding inventory, and the demand for the inventory. By using EOQ, businesses can ensure that they are ordering the right amount of inventory at the right time, reducing inventory carrying costs and increasing profitability.

Safety Stock

Safety stock is a buffer of inventory that businesses keep on hand to ensure that they do not run out of stock during unexpected demand spikes or supply chain disruptions. By maintaining an appropriate level of safety stock, businesses can reduce the risk of stockouts and lost sales, which can negatively impact revenue and profitability.

Implementing Inventory Management Software

One of the main benefits of inventory management software is that it can help businesses reduce the costs associated with overstocking and understocking. By tracking inventory levels in real-time, businesses can ensure that they have the right amount of inventory on hand to meet customer demand. This can reduce the need for emergency orders, which can be costly and time-consuming.

Another benefit of inventory management software is that it can help businesses automate the purchasing process. With the right software, businesses can set up automatic reordering when inventory levels reach a certain threshold.

Inventory management software can also help businesses improve their forecasting capabilities. By analyzing historical sales data, businesses can make more accurate predictions about future demand.

When implementing inventory management software, businesses should consider integrating it with their point of sale (POS) system. This can help businesses track inventory levels in real-time and ensure that they have accurate data on hand to make informed purchasing decisions.

Conclusion

Inventory management is a crucial aspect of any business that deals with physical products. By implementing effective inventory management practices, businesses can reduce costs and improve their bottom line.

Overall, effective inventory management can help businesses reduce costs, improve cash flow, and increase customer satisfaction. By implementing best practices and utilizing inventory tracking software, businesses can stay ahead of the competition and achieve long-term success.